We transfer emotions

into products

Inebi GmbH

from Gummersbach

Inebi GmbH sees itself as a developer and producer of

technical and decorative plastic parts.

- 2014: Established in Gummersbach Ingenieurgesellschaft Binder

- 2019: Building of new factory

- 2020: Starting production in the new factory

Our technologies

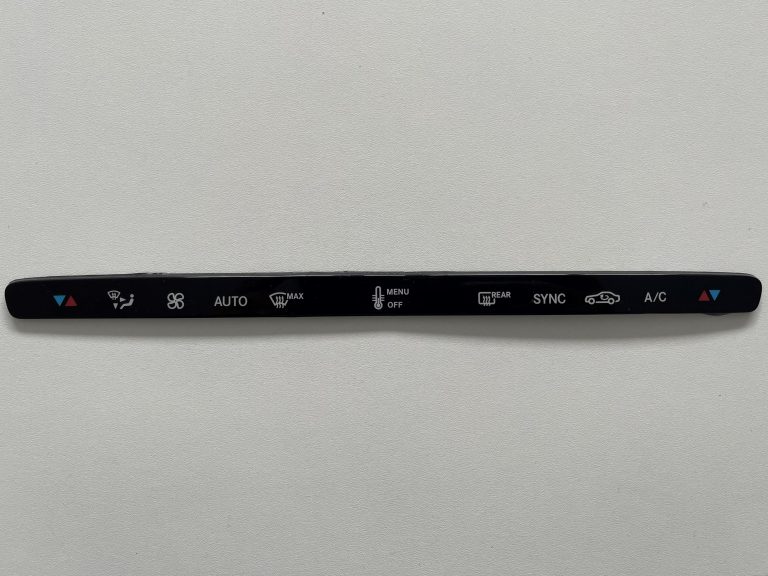

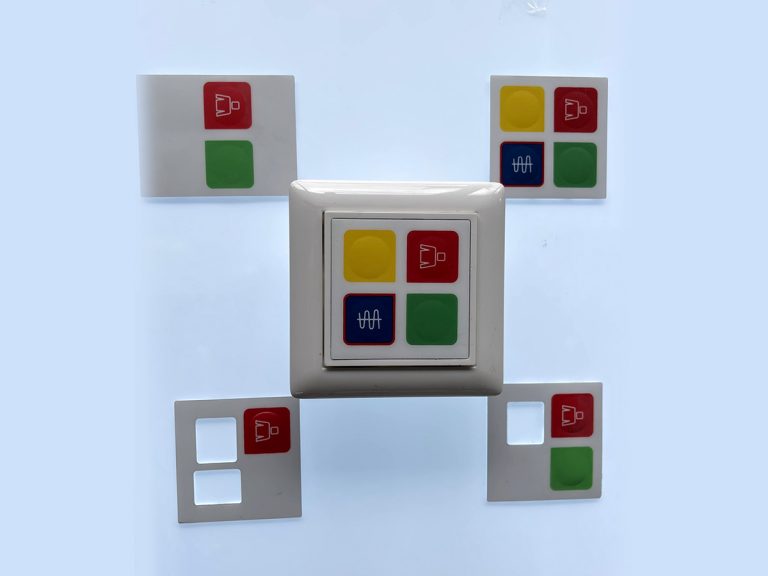

Printing Technology

Screen printing process under cleanroom conditions.

Plastic films are screen-printed under controlled parameters regarding temperature and humidity conditions. Highest standards of accuracy and reproducibility are fulfilled during the process.

The cutting technology

Camera-controlled punching processes guarantee the required tolerances of +/- 0.1 mm.

Depending on the requirements strip steel cuts or solid tools are used.

CO2 Laser cutting / engraving

In the development phase,films can be cut with tolerances of +/- 0,05 mm

Prototypes and preserial parts can be produced in short time.

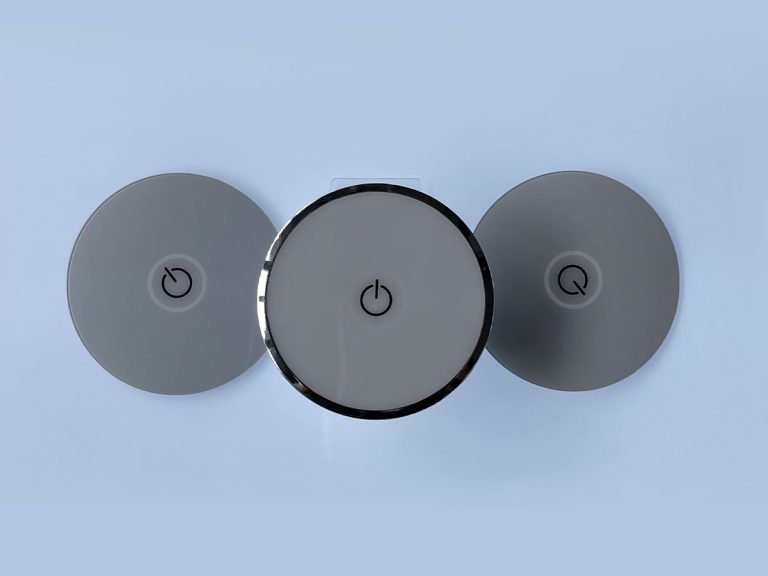

Preforming

We realize positionally accurate preformed parts for 3D application.

Printed Electronics /

Smart Films

Combination of design and functionality.

Printing of different pastes and lacquers for the production of capacitive touch and sensor technology.

What we do

Our products

INEBI describes itself as a competent development partner and serial production supplier for large-scale industry in the fields of household appliances, automotive and medical technology.

Do you have any questions to our products?

Our quality

Quality is an fundamental component of our company philosophy.

Our certification of the quality management system according to DIN EN ISO 9001 is the consistent implementation of our company philosophy. It is our responsibility and obligation towards our environment and future generations, to introduce an environmental management system. The certification according to DIN EN 14001 means for us to have the sustainability of our processes and products always in focus.

For us, quality begins in development, with a feasibility study. Due to a close cooperation with our customers, we establish a “zero defect strategy” in a very early stage of the project.

Our quality assurance starts with quality planning (FMEA), through the design of manufacturing processes and procedures, to 100% control of our products.

We involve our suppliers to fulfill all the requested quality standards.

Become part of our team!

To apply for one of our jobs , please send us your

application documents by e-mail to info@inebi.de

Any questions?

How to find us

Inebi GmbH

Martin-Siebert-Str. 3a

51647 Gummersbach

Tel. +49 2261 / 9111517

Fax +49 2261 / 9111518

Email: info@inebi.de